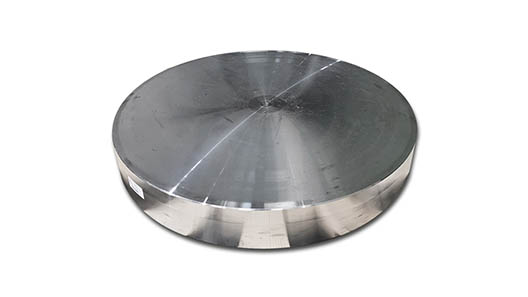

Stainless Steel 317L Forged Discs

Ferrobend is a renowned name in the manufacturing of stainless steel products, including the production of high-quality 317L forged discs. Known for our commitment to precision, innovation, and the highest standards of material quality, we provide industry-leading solutions tailored to meet the specific requirements of our clients. Let’s delve into the features, benefits, and manufacturing processes that make Ferrobend a trusted supplier of Stainless Steel 317L Forged Discs. Forged discs made from Stainless Steel 317L combine the best of both worlds – the strength and durability of the forged process, with the corrosion-resistant properties of Stainless Steel 317L. These discs are used in various sectors, including petrochemical industries, power generation, marine applications, and food processing systems.

Stainless Steel 317L is a low-carbon version of Stainless Steel 317, designed to enhance its weldability while maintaining the superior corrosion resistance and high strength of the base material. Comprising primarily of chromium, nickel, and molybdenum, 317L offers excellent resistance to pitting and crevice corrosion in harsh environments. This alloy is particularly resistant to sulfuric and phosphoric acids and other aggressive chemicals, making it ideal for industries dealing with harsh chemical environments. The "L" in 317L denotes low carbon content, which minimizes the risk of carbide precipitation during welding, making it highly suitable for welded applications. In addition to its resistance to corrosion, Stainless Steel 317L also maintains good mechanical properties, making it a highly effective material for products that must withstand high temperatures and mechanical stress.

Forging is a process that involves shaping metal using compressive forces. In the case of stainless steel 317L forged discs, the forging process enhances the material’s grain structure, improving its strength, toughness, and fatigue resistance. This makes the discs suitable for applications that demand high-performance materials capable of withstanding intense conditions, such as extreme pressure, high temperatures, and exposure to corrosive environments.

Ferrobend is committed to producing stainless steel 317L forged discs of the highest quality. Our manufacturing process follows a strict quality control system to ensure that every product meets industry standards and customer specifications. The foundation of any quality forged product is the selection of premium raw materials. At Ferrobend, we carefully source only the highest-grade stainless steel 317L billets or ingots from trusted suppliers. The material is selected based on its chemical composition, ensuring it meets the specific standards required for use in the forging process.

Once the raw material has been selected, it undergoes heating in an industrial furnace to a specific temperature suitable for forging. This heat treatment ensures that the material becomes malleable, allowing it to be shaped without compromising its internal structure. The billets are then subjected to high-pressure mechanical forces that shape them into the desired disc forms. Ferrobend uses state-of-the-art forging presses and hammers that provide uniform force, ensuring that each forged disc meets our strict dimensional and mechanical standards. The result is a product with enhanced structural integrity and uniformity.

The forged discs then undergo precision machining to achieve the exact dimensions, surface finishes, and tolerances specified by the customer. At Ferrobend, we employ advanced CNC (computer numerical control) machines and other high-precision tools to ensure that the forged discs are accurately shaped and finished to meet stringent industry standards.