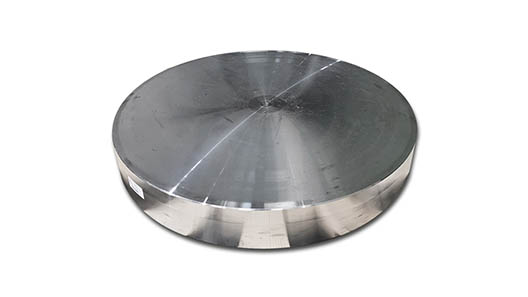

Stainless Steel 317L Forged Flanges

Stainless steel 317L forged flanges are critical components used in various industrial applications, known for their high resistance to corrosion, superior strength, and durability. These flanges are an essential part of pipe systems, helping in connecting pipes, valves, pumps, and other equipment in chemical, petrochemical, food processing, and many other industries. Ferrobend, a leading manufacturer, ensures that their stainless steel 317L forged flanges meet the highest industry standards and offer exceptional performance. This combination makes 317L particularly useful in environments with high temperatures and aggressive chemicals.

Stainless steel 317L is an austenitic chromium-nickel stainless steel alloy that is specifically designed to offer excellent resistance to corrosion and oxidation in highly aggressive environments. The "L" in 317L refers to the low carbon content, making it less prone to sensitization and carbide precipitation, which can occur in high-temperature environments.

Forged flanges are created through a forging process, where metal is shaped under high pressure to form the desired shape. This process imparts superior strength, durability, and resistance to wear and tear, making forged flanges a better choice over cast flanges in many applications. The forging process ensures that the metal's grain structure is tightly packed, resulting in a more robust and reliable product.

Stainless steel 317L forged flanges are frequently used in the oil and gas industry for high-pressure pipelines and components. They can withstand the extreme conditions found in offshore drilling and refining processes. Ferrobend offers custom manufacturing services, allowing clients to specify the exact dimensions, pressure ratings, and finishes needed for their applications. Whether you need ANSI, ASME, or API standards, Ferrobend can deliver flanges tailored to your specifications.

Ferrobend has years of experience in manufacturing high-quality flanges and fittings. Their team of experts is well-versed in the complexities of material selection, manufacturing processes, and testing to ensure that every product meets the required standards. Ferrobend uses only premium quality stainless steel 317L to manufacture forged flanges. The company sources its materials from trusted suppliers, ensuring that each flange possesses the desired properties of corrosion resistance, strength, and durability.

At Ferrobend, quality control is paramount. Every batch of stainless steel 317L forged flanges undergoes thorough testing, including dimensional checks, pressure tests, and material composition analysis. The company also ensures compliance with international standards like ASTM, ASME, and EN. Ferrobend understands the importance of timely delivery in industrial projects. They ensure that all stainless steel 317L forged flanges are delivered on time, even for urgent orders. With an efficient supply chain and extensive stock availability, customers can rely on Ferrobend for quick lead times. Ferrobend provides competitive pricing without compromising on quality. By offering cost-effective solutions for stainless steel 317L forged flanges, Ferrobend makes it easier for companies to stay within budget while ensuring they receive top-quality products. Stainless steel 317L forged flanges manufactured by Ferrobend are ideal for industries that require superior corrosion resistance, strength, and durability. Ferrobend’s commitment to quality and expertise in manufacturing ensures that these flanges are perfectly suited to meet the demands of harsh environments.