Stainless Steel 317L Forged Valves

Stainless Steel 317L forged valves are a top choice in industries worldwide. These valves, known for their exceptional strength, durability, and corrosion resistance, are designed to meet the stringent requirements of industries such as oil and gas, chemical processing, power generation, and more. Among the leading manufacturers of stainless steel forged valves, Ferrobend stands out as a trusted provider offering precision-engineered, high-quality valves that cater to diverse industrial applications. Stainless Steel 317L Forged Valves manufactured by Ferrobend, highlighting why they are a preferred choice for engineers and procurement specialists across the globe.

Stainless Steel 317L is an austenitic stainless steel alloy that contains high levels of molybdenum, which gives it enhanced resistance to corrosion compared to standard stainless steels like 304 and 316. The “L” in 317L refers to its low carbon content (0.03% max), making it less prone to carbide precipitation during welding and enhancing its overall resistance to stress corrosion cracking. This combination of features makes Stainless Steel 317L an excellent choice for applications in highly corrosive environments such as marine, chemical, and food processing industries.

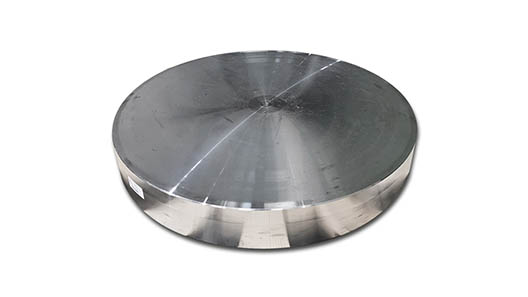

Forging is a manufacturing process that involves shaping metal through localized compressive forces. Unlike casting, forging ensures a stronger, more durable product because the metal's grain structure is aligned, making it more resistant to wear and stress. Ferrobend utilizes advanced forging techniques to produce Stainless Steel 317L forged valves, resulting in products that boast superior mechanical properties, reliability, and longevity. Forged valves have better performance characteristics than cast valves, especially under high pressure and temperature conditions. The precision in the forging process allows for better sealing performance and a more robust structure, minimizing the risk of failure under demanding conditions.

The 317L alloy exhibits excellent resistance to oxidation at elevated temperatures, making it an ideal material for applications that require valves to function effectively under heat stress. Whether in high-temperature chemical reactors or power generation plants, Ferrobend’s forged valves provide reliable service, even in extreme thermal conditions.

Ferrobend employs cutting-edge manufacturing techniques to create valves with precise tolerances, ensuring that each valve fits seamlessly into the intended pipeline or system. The company’s attention to detail during the forging process results in valves that offer superior sealing capabilities and a longer service life.

Ferrobend’s Stainless Steel 317L forged valves are available in various designs, including ball, globe, gate, check, and butterfly valves. This versatility allows engineers to select the appropriate valve type for their specific application, further enhancing the overall performance of the system. Ferrobend is a renowned manufacturer of high-quality valves, and their commitment to excellence is evident in their Stainless Steel 317L forged valves. The company prides itself on providing robust, corrosion-resistant, and highly durable valves that cater to the most demanding industrial applications. With advanced manufacturing processes, stringent quality control, and a focus on customer satisfaction, Ferrobend has earned the trust of engineers and procurement professionals across the globe.